聯系我們

18560023440

王經理:18560023440

地址:山東省德州市齊河縣經濟開發區齊眾大道7號-2車間

業內資訊

業內資訊

石材雕刻機加工過程中冷卻的重要性

來源:http://www.v8fpm.cn 時間:2021-01-26

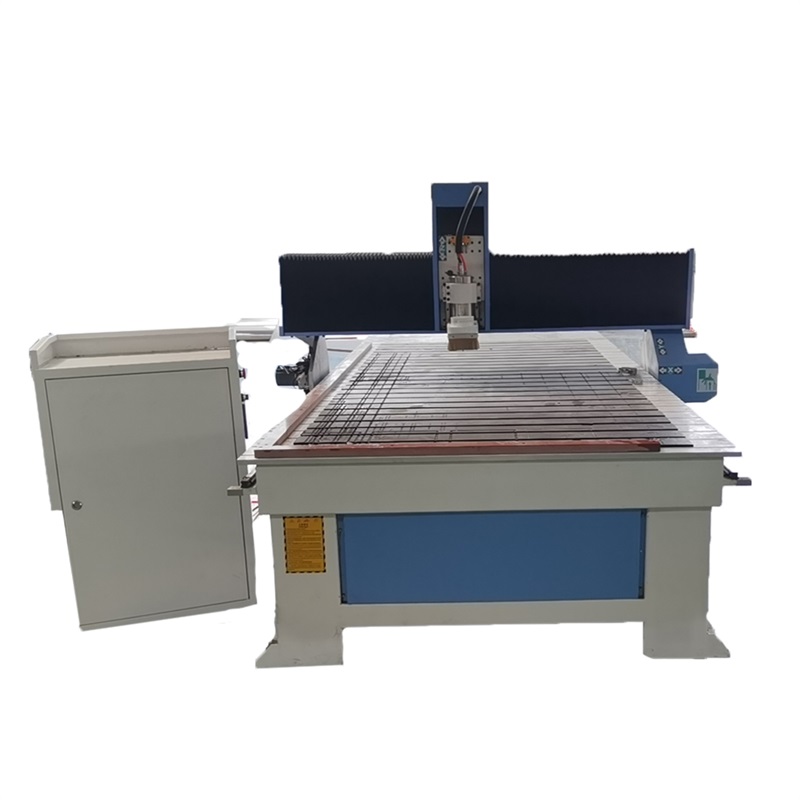

市面上大多數的數控石材雕刻機都是采用雙冷卻的,而石材加工過程中加水有什么作用呢?其實是因為石材的材質都比較硬,所以在雕刻過程中需要水冷刀頭。

Most of the CNC stone engraving machines on the market adopt double cooling, and what is the role of adding water in the process of stone processing? In fact, because the stone material is relatively hard, so the water-cooled blade is needed in the carving process.

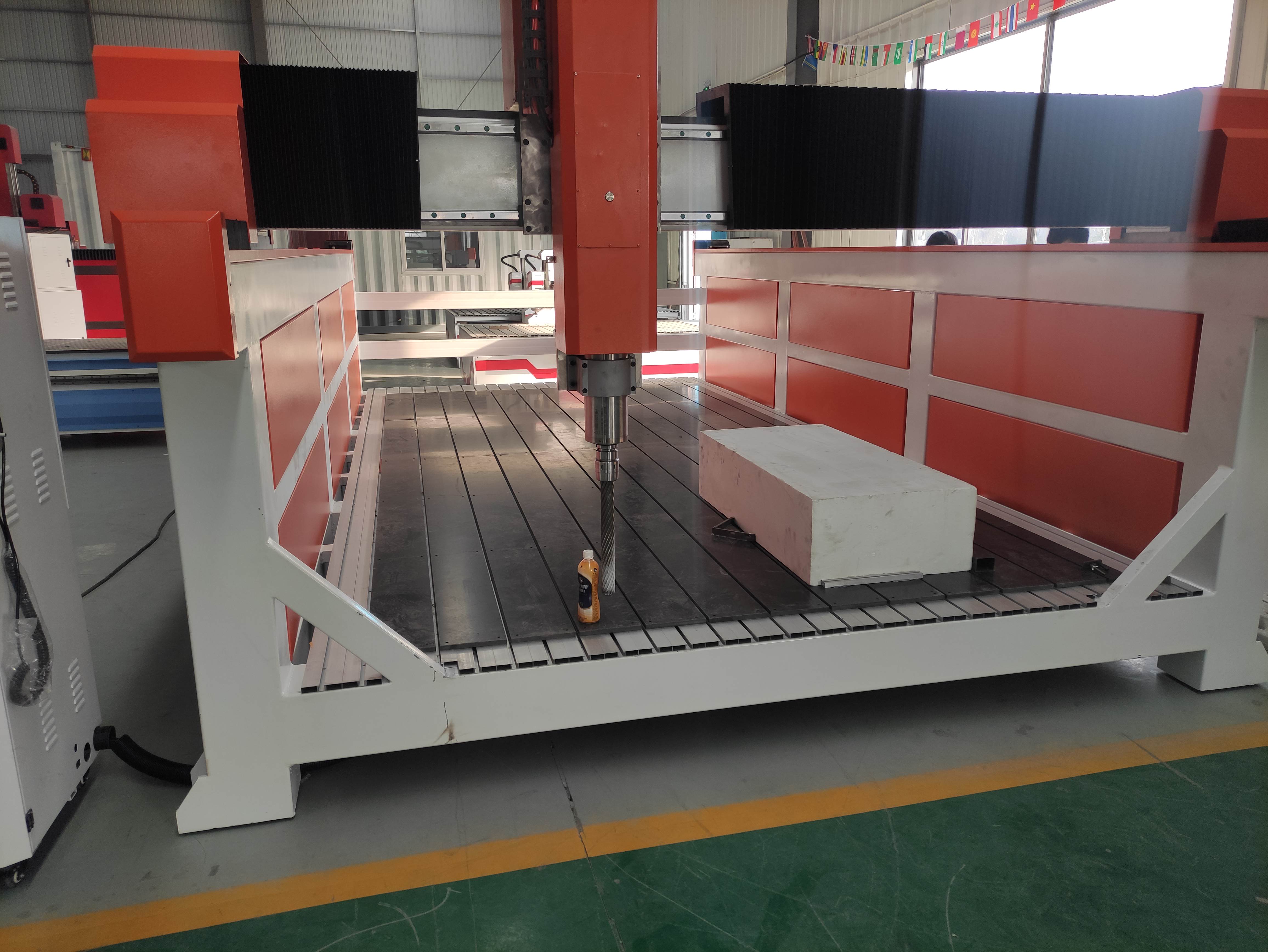

另一方面是采用水冷卻雕刻機主軸,防止主軸的溫度過高,起到一定的保護作用。如果雕刻機操作人員不注意冷卻或者沒有按照步驟進行操作的話,很容易會導致石材雕刻機不通水干燒的情況,對設備造成嚴重的損害。

On the other hand, it uses water to cool the main shaft of engraving machine to prevent the temperature of the main shaft from being too high. If the engraving machine operators do not pay attention to cooling or do not follow the steps, it is easy to lead to the stone engraving machine without water and dry burning, causing serious damage to the equipment.

數控石材雕刻機在加工過程是必須要采取冷卻辦法的,如果雕刻機沒有通水冷卻,主軸會一直處于持續高溫發熱的狀態。很容易會導致雕刻機主軸出現抖動或者錯位,雕刻的速度忽快忽慢,加工過程是很不穩定的。石材雕刻機主軸會直接影響到雕刻的精度,而且主軸錯位的話會使雕刻的工件發生錯位,加工出來的石材會受到嚴重的影響。

CNC stone engraving machine in the process of processing must take cooling method, if the engraving machine is not water cooling, the spindle will always be in a state of continuous high temperature heating. It is easy to cause the engraving machine spindle jitter or dislocation, engraving speed is fast and slow, the processing process is very unstable. The main shaft of stone carving machine will directly affect the accuracy of carving, and if the main shaft is misplaced, the carving workpiece will be misplaced, and the processed stone will be seriously affected.

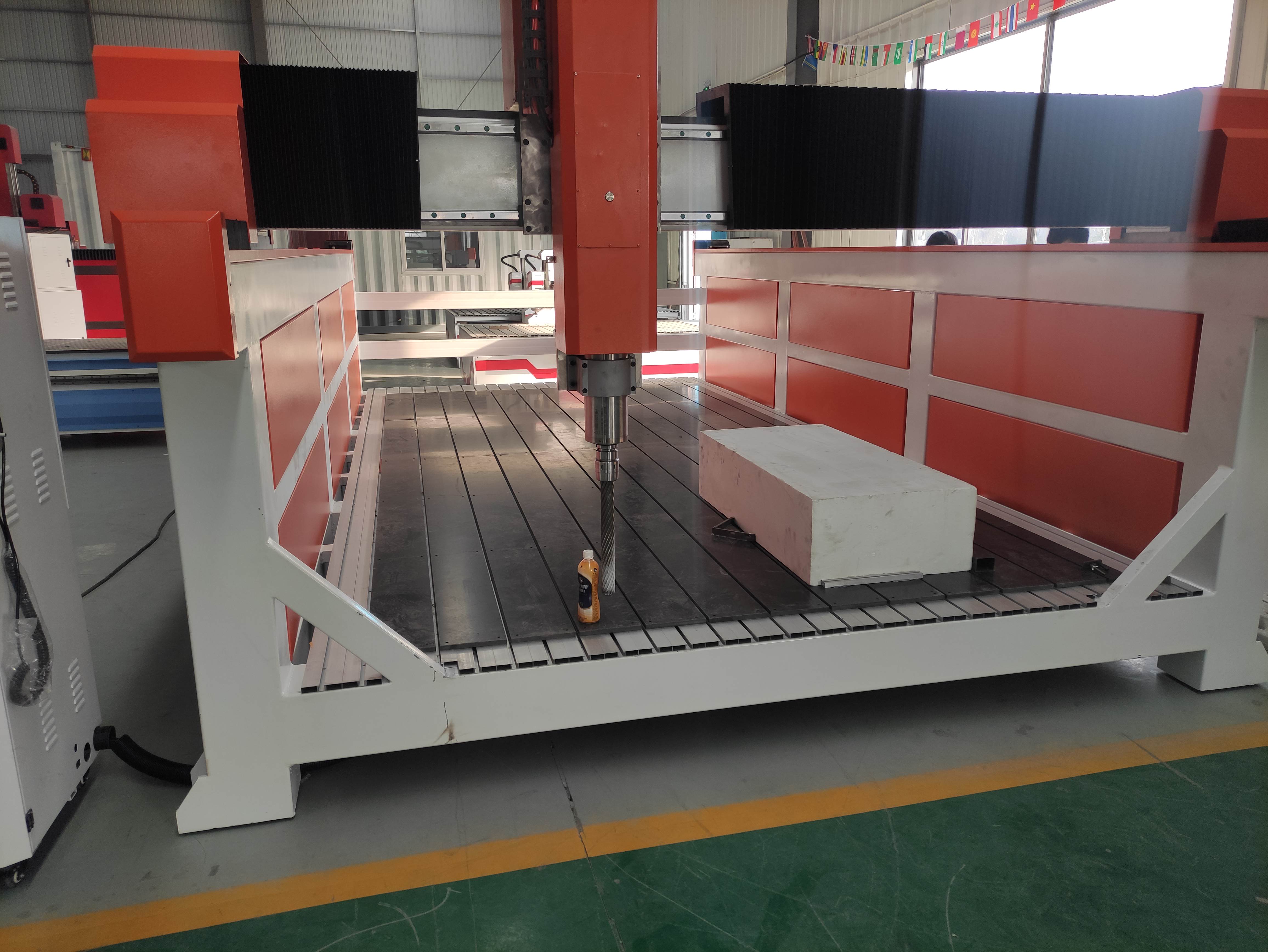

如果石材雕刻機主軸干燒會引起主軸發熱過度,導致雕刻機主軸因為溫度過高而燒掉。主軸是雕刻機的重要部件,如果出現損壞的情況就需要返廠維修或者更換新的主軸。

If the stone engraving machine spindle dry burning will cause excessive heating of the spindle, resulting in engraving machine spindle burning because of high temperature. Spindle is an important part of engraving machine. If it is damaged, it needs to be repaired or replaced.

無論是檢修還是更換,都會嚴重耽誤石材雕刻機的加工工期,特別是訂單量大、工期緊張的時候,因為雕刻機無法正常運轉而給企業造成嚴重的損失。因此,石材雕刻機在加工過程中必須要按照廠家培訓的正規操作,保證設備的,才能給企業帶來更大的效益。

Whether it is maintenance or replacement, it will seriously delay the processing period of stone carving machine, especially when the order volume is large and the construction period is tight, because the carving machine can not operate normally and cause serious losses to the enterprise. Therefore, stone carving machine in the process of processing must be in accordance with the normal operation of factory training, to ensure the safety of the equipment, in order to bring greater benefits to the enterprise.

- 上一篇:石材雕刻機出現錯位現象是什么原因?

- 下一篇:五軸雕刻機的價值評估標準有哪些?